|

Unparalleled Cutting Speed and Capacityl

|

|

|

|

|

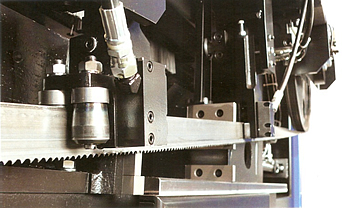

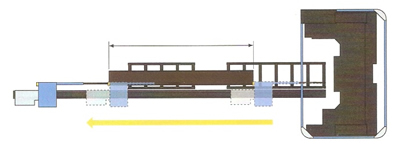

The cutting feed rate of DB3C5030 is controlled by a servo motor and a ball screw for high speed and accurate cutting condition. A tensioned bandsaw blade could cut most profiles up to 500mm-wide/300mm-high section faster and quieter than circler saw blade, bringing lower running costs. |

|

Time Study

|

|

|

|

|

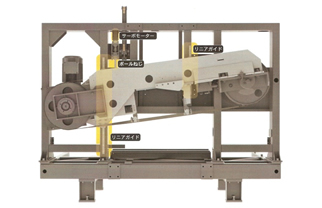

Servo controlled cutting feed rate

|

|

|

|

|

|

The servo-motor-ball-screw feed method is not affected by temperature, unlike hydraulic method; always accurate and stable. |

|

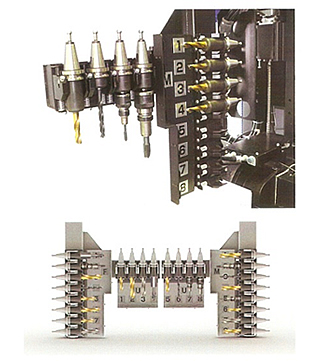

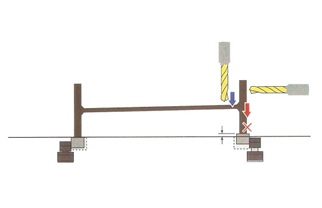

Automatic Tool Changer (ATC)

|

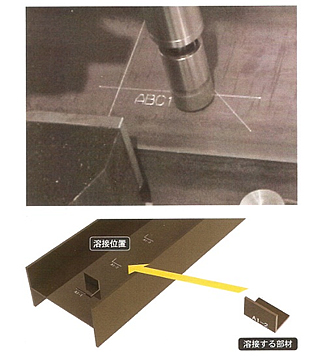

Scribing

|

|

|

|

|

Each drill unit has a tool magazine which can store maximum 8 tools for holes of different diameters, tapping and marking. The tools are replaced automatically. |

Lines and numbers can be scribed by the drill spindle with scribing bit. They are clearly marked on material surface and it saves time from marking by hand. |

|

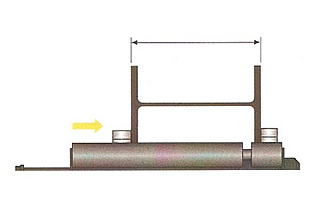

Length Measurement

|

|

|

|

|

The material length measurement is made when infeeding material to the machine. |

|

Wide Measurement

|

Flange Height Gauge

|

|

|

|

|

The guide roller measures the material width. |

Even distored material, hole position is compensated by the flange height gauge. |